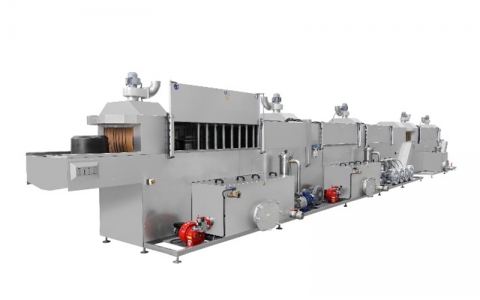

TWM 100 Series Tunnel Parts Washing Machine

USAGE AREAS

Automotive Industry

Aircraft Industry

Shipbuilding Industry

Military Industry

Metal Industry

WORKING PRINCIPLE

The materials to be washed are placed in a basket or directly on the speed-adjustable conveyor belt. The materials to be washed pass through the spray washing unit, spray rinsing unit, air blowing and drying units respectively and arrive at the unloading platform.

Continuous continuous washing can be performed by hand or by means of a conveyor system. The nozzles are designed to scan every point of the material.

Surface cleaning of the desired quality can be achieved by adjusting the washing pressure, nozzle placements and processes according to the oil, sawdust and residue in the material to be washed.

Depending on the process, the unit can be increased or decreased as desired.

Our company can manufacture parts washing machines in desired sizes and features.